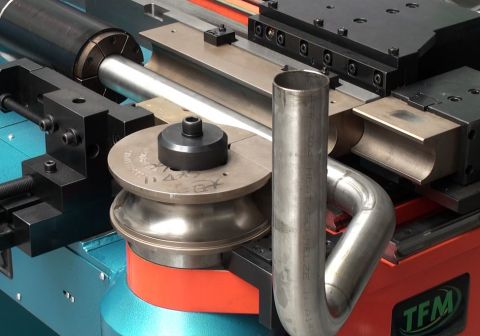

CNC BENDING MACHINES

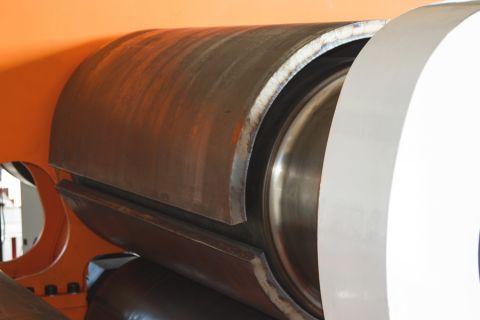

CNC automatic benders are highly efficient mandrel benders intended for bending pipes, sections and bars which prove perfect in serial production. The machines are equipped in two servomechanisms responsible for material stroke and rotation, PLC controller as well as hydraulic system which controls the other working motions, including the bending axis. CNC benders described are one-pile machines intended for bending with constant radius with the method involving winding of the material on the bending mould.

The machines are dedicated for serial production and processing of complicated, in terms of shape, spatial workpieces. With adequate equipment configuration, they allow obtaining high quality bends for thin-walled pipes and sections and with small radii. The model offer is similar to the offer comprising other economic benders of the manufacturer, these are from GM-38CNC-2A-1S model (bending of pipes with the diameter >Ø38mm) to GM-325CNC-2A-1S model (with the bending efficiency of max. Ø325mm).

The most important functions and advantages:

- in order to assure high accuracy and repeatability of bent workpieces, the material stroke and rotation is realized with the use of servomechanisms,

- central hydraulic system equipped in oil control and cooling system is responsible for other working motions, including the bending axis drive,

- the header configuration allows bending of constant radius without the possibility of material winding up or generation of irregular radii,

- the device is controlled with the use of touch graphic panel with Polish servicing system and possibility of saving up to 200 processing programmes with 10 bends of various angles each,

- the standard equipment of the machine comprises the guide mould stroke servomotor (the so-called booster), arms which reinforce the shaft with the bending and guide mould clamp, controlled mandrel return and reverse bending function,

- possibility of modification in terms of the mandrel working length, bending header size, etc.