NC BENDING MACHINES

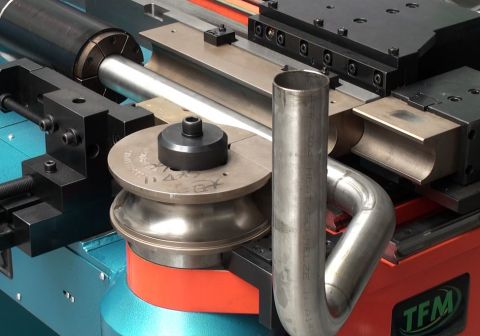

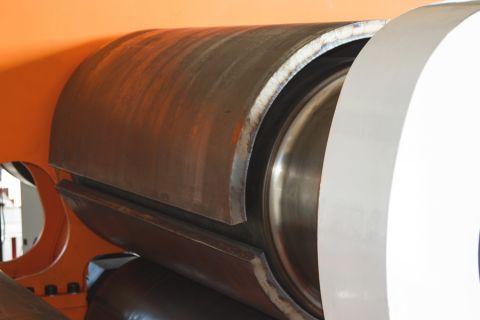

Semi-automatic mandrel benders prove perfect in the plants of medium production load. Economic in terms of purchase and maintenance, the benders are perceived as one of the most popular mandrel benders available on the market. This is why, inter alia, they are available in a wide variety of models starting from the machines used for bending pipes with the maximum diameter of Ø38mm to benders with the maximum bending efficiency of Ø325mm. With the proper equipment configuration, they allow for obtaining high quality bending for thin-walled pipes and sections and with small radii.

The most important functions and advantages:

- all working motions, with the exception of feeder rotation, are realized with the help of central hydraulic system equipped in oil control and cooling system,

- the operator is responsible for material shift and rotation between the given bends,

- control takes place with the use of operation panel (Polish) with the possibility of saving up to 200 processing programmes with 10 bends of various angles each,

- the standard equipment of the machine comprises the guide mould stroke servomotor (the so-called booster), arms which reinforce the shaft with the bending and guide mould clamp, controlled mandrel return and reverse bending function

- possibility of modification in terms of the mandrel working length, bending header size, etc.

When selecting the machine, it is worth to pay attention to the very essential fact concerning the role and involvement of the operator in the material bending process. As far as the discussed NC semi-automatic mandrel benders with the feeder are concerned, the operator is responsible only for the material shift between the given bends. The control over the applicable material shift is made easier due to the list with the measure which at the same time guarantees the production repeatability. While the change of the bending plane is realized automatically by the operator. If such is the case, in order to assure high production repeatability, it is necessary to equip the machine in optional positioning plates. The offer comprises, both basic versions of NC semi-automatic benders with feeders, in which the material rotation is carried out automatically and driven by means of a servomechanism.